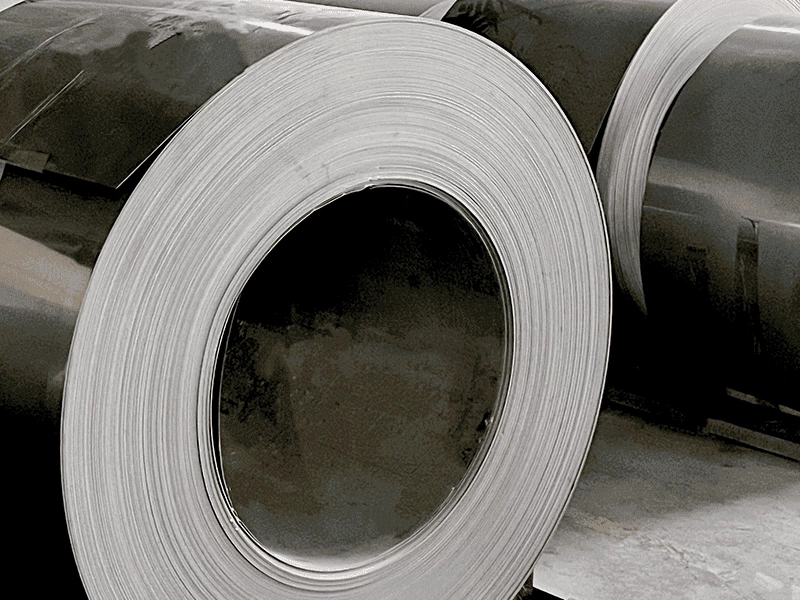

Step 1

Raw Material Procurement

We insist on using internationally certified food-grade stainless steel, mainly 304 or higher grades, to ensure excellent corrosion resistance, heat tolerance, and mechanical strength.

Each batch of material must pass composition testing and mechanical inspections such as tensile strength and thickness uniformity before entering production.

We maintain long-term partnerships with trusted steel suppliers to ensure stable sourcing, laying a solid foundation for consistent quality in mass production.