Grade 304,316 Stainless Steel Material: Properties and Applications

Choosing the right stainless steel material is the most critical decision in kitchenware manufacturing. For B2B buyers and importers, the difference between grades determines not only the production cost but also the product's longevity and performance in a commercial kitchen.

At DSkitchenware, we prioritize material transparency. This guide breaks down the stainless steel material composition and properties of the most common grades—304, 316 to help you make informed procurement decisions.

Quick Comparison: Stainless Steel Grades at a Glance

Before diving into the details, here is how the grades compare in a manufacturing context.

| Grade | Common Name | Magnetic | Key Element | Best Application |

|---|---|---|---|---|

| 304 | 18/8 or 18/10 | No | 18% Cr, 8% Ni | Cookware bodies, Sinks, Food processing |

| 316 | Marine Grade | No | Added Molybdenum | arine environments, Saline food storage |

Grade 304 (18/8) Stainless Steel: The Industry Standard

Type 304 is the most versatile and widely used stainless steel in the kitchenware industry. It is frequently referred to by its traditional designation, 18/8 stainless steel material, which refers to its nominal composition: 18% chromium and 8% nickel.

304 Stainless Steel Material Properties

Why is 304 the dominant choice for high-quality pots and pans?

-

Deep Drawability: 304 is an austenitic grade with high ductility. It can be "deep drawn" into complex shapes (like deep stockpots) without cracking during the stamping process.

-

Corrosion Resistance: The high nickel content creates a passive layer that protects the steel from rust in standard cooking environments (water, steam, mild acids).

-

Hygiene: Its non-porous surface prevents bacterial growth, making it the standard for food-grade certifications.

DSkitchenware Manufacturer Insight: "We often see competitors substituting 304 with 201 stainless steel to lower costs. While 201 looks identical when new, it has low nickel content and will rust significantly faster. For premium cookware, we strictly adhere to 304 (18/8) specifications."

Best Applications for 304 in Kitchenware

Unlike general industrial steel, in the context of food service, 304 is best used for:

- Cookware Bodies: High-quality saucepans, frypans, and stockpots.

- Food Processing: Brewery tanks, dairy equipment, and commercial mixers.

- Sanitary Areas: Commercial kitchen sinks and splashbacks due to ease of cleaning.

- Pet Industry: Stainless steel litter box

Grade 316 Stainless Steel: The Premium Upgrade

316 stainless steel material properties are defined by one significant addition: 2% to 3% Molybdenum.

While 304 is excellent for general use, 316 stainless steel material offers superior resistance to specific types of chemical attacks, particularly pitting corrosion caused by chlorides (salt).

When Should You Choose 316 Over 304?

Upgrading to 316 increases raw material costs by approximately 20-30%. It is worth the investment only in specific scenarios:

-

Food and Beverage: It is used as food-grade stainless steel and dairy machinery due to its resistance to food acids and ease of cleaning.

- High-Salinity Environments: Cookware used on yachts, near oceans, or for processing salty brines.

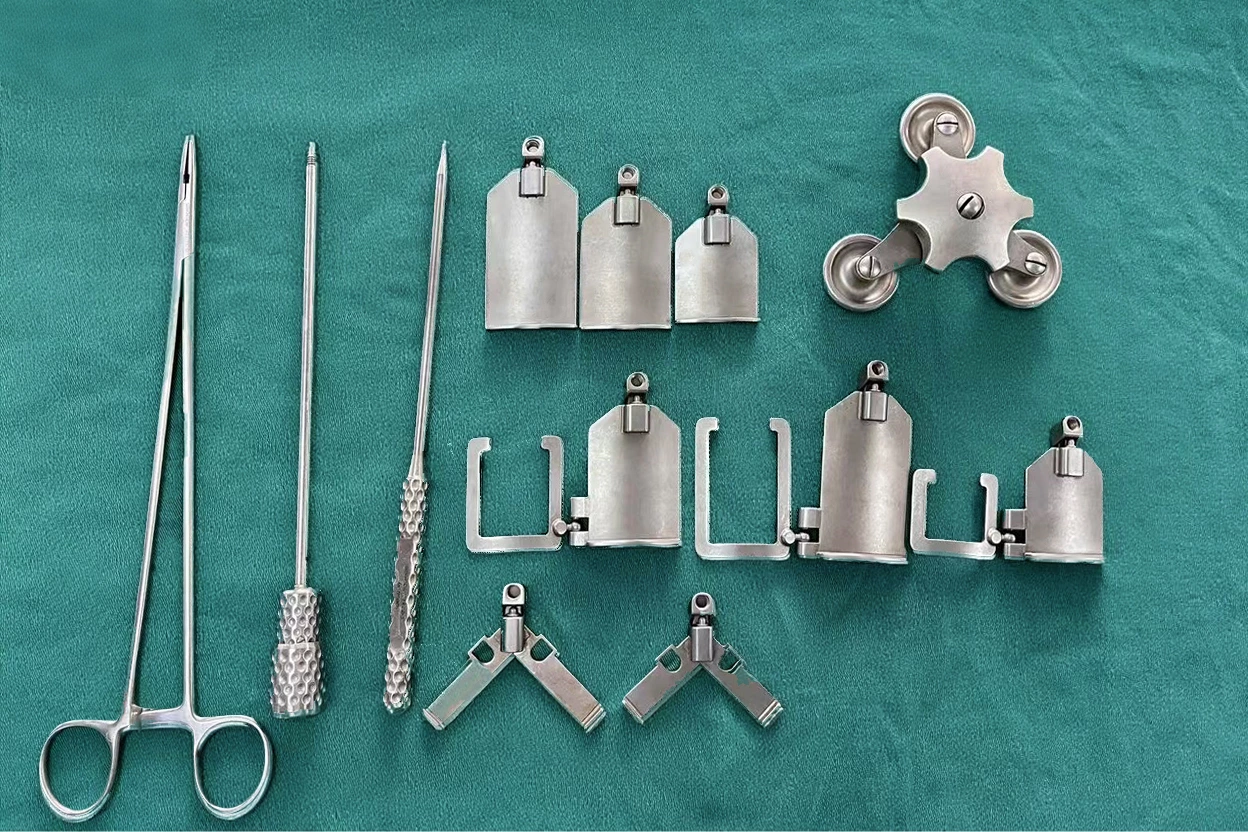

- Medical Devices: Surgical instruments, orthopedic implants, and dental equipment.

- Long-term Storage: Vessels designed to hold acidic sauces or marinades for extended periods.

Conclusion: Matching Material to Product

The success of your kitchenware product line depends on selecting the right material for the right function:

Use 304 (18/8) for the main body of pots, pans, and sinks.

Use 316 for high-end marine or chemical-resistant specifications.

At DSkitchenware, we specialize in customizing the material composition to balance your budget and quality requirements.

Need a quote for 304 vs 316 cookware? [Contact our engineering team today] to discuss your project.